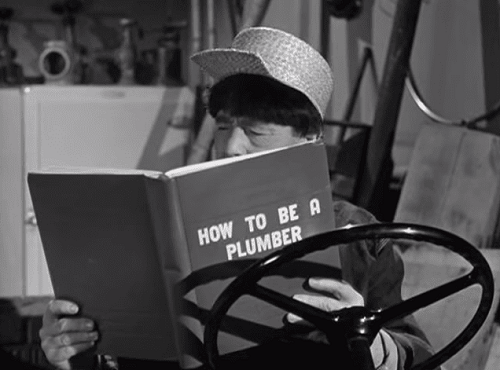

You may recall that last summer, my father-in-law and I tackled a plumbing issue at our house. That incident required us cutting up the drywall to access pipes. The results were not pretty.

The above picture was taken during the project. We were able to get pipes fixed and the hole has remained in the wall ever since. This is partly because there is always someone sleeping in the bedroom where the repair has to be made.

I digress.

Way back in the summer, my wife asked me to apply for a Menard’s card. I kept meaning to do it. I was going to do it the last time I was in there, but I had both kids with me and they were anxious to leave.

After talking about the hole in the wall, and how I need to get an access panel for it, I decided to go on their website to apply for their credit card. I figured if I got approved for a couple hundred bucks, that was all I needed to get the things for the bedroom. Well, I was approved – for a much larger amount!

I have to really take a step back and remember that I don’t need to spend that much money. However, there are things that need to get done (and haven’t) because the budget didn’t allow for it. The access panel – has to be done.

The thing is going to cost like $50 and depending on the hole in the wall, and such, I may need to patch a bit of the drywall. $50! It’s a plastic door for crying out loud, but ok. I need to get it done.

All of the doors in our house have the handles that look like this:

Personally, I like them. However, they are perfect for Andrew to get to – and open. Sam and I discussed switching them all over to the round brass handles.

Some of them will have locks on them. Those will need to have the “easy unlock” from the other side, in case the kids lock themselves in a room. You know, the notch you can put a butter knife in and turn? And the round door knobs will allow us to put those childproof covers on that the kids can’t turn.

So, we have the access panel project and the door knob project. There are still a couple other projects.

Our bedroom had a ceiling fan/light fixture in it. The bulbs are all halogen and extremely hard to find. If you can find them, they are like $30 apiece. The entire fixture has 5 lights in it and currently only has one that works. Thank goodness for the lamp on my bedside table! Sam has been talking about getting rid of the whole thing and just putting in a regular light since we moved in together.

Something as simple as the light above – or something even more simple – would work. So that project is also on the list.

Finally, in our living room, the ceiling fan/light has needed to be replaced for some time. This should be an easy swap since we are just going to get another light/fan fixture.

At some point, we’d love to do something with the lighting in our kitchen, but that’s probably enough projects for now. Unless my father-in-law and I can figure out a way to build a deck in the back of the house really cheap! It couldn’t hurt to just price it all out, right?!